This is the rendering and the drawings that I made to build this toy box.

Tuesday, November 22, 2011

Friday, June 17, 2011

Garden Time

We are trying out some pumpkins this year! I have the seedlings growing inside the house right now under some 48" fluorescent lights. I built a simple plywood stand out of some scrap to mount the lights to. This works really well and I think I bought the light fixtures for like 8 bucks at home depot.

Here is the light stand I built. I did a lot of research on the web and found tons of people using this method. These light fixtures are much cheaper compared to grow lights you would find at a hydroponics store, but still very effective. I am still very new to gardening and this is only my third time starting plants using this approach. I would say that in my experience this is an exceptional way to start your plants from seeds. We have started Watermelons, Cayenne peppers, Bell peppers, Serrano peppers and now Pumpkins with this set up. I just hope that I started the pumpkins early enough for Halloween.

The bigger one on the right sprouted in like 4 days. I was really surprised that they germinated so fast hopefully they maintain this growth. The one to the left popped up a few days later.

This guy seems to be a little lazy almost a week and a half later finally popping.

As you can see the wood projects we do can sometimes be something very simple. This is a very easy project that almost anyone at any skill level can complete with minimal tools. Me and my family really enjoy growing fruits and vegetables that we can benefit from and we are teaching our children how to maintain a healthier lifestyle.

Labels:

garden

Dezert Life

Just a few pics of some reptiles I have found on our property. I have been trying to get some pictures of the cotton tails and there is one squirrel in my neighbors back lot that I have not been able to get a shot of yet. We live in a semi rural area so there is tons of wild life to enjoy.

This little dude is the Desert Spiny Lizard, Sceloporus Magister is the technical name for this guy. I found him right next the the shop.

This guy is a long nose snake, Rhinocheilus Lecontei is the technical name for this snake. My wife found this shy guy in the back yard, our dogs were going crazy. I relocated him so that he could be on his way.

Labels:

wild life

Tuesday, June 14, 2011

R U Square

Here are some solid model renderings of the 6in square that I would like to make. My plan for these guys are to aid in assembly work, plus who doesn't need super awesome precision square. I will make these out of some scrap aluminum we have at work. The CNC milling machine will make quick work of this item. I plan on making a handful as I see so many ways this tool can be useful in the shop. The counterbored through holes will allow me to screw it to a bench and clamp to it. The six threaded holes I will use to attach a stop fence, this will help align the face of two boards with out having to think twice about it. Just a cool little tool that I need to get some time to make.

Labels:

tools

Friday, June 3, 2011

Ben & Kristen's cutting board PART 3

I finally finished the end grain cutting board that I was working on and just in time. This particular cutting board was a wedding gift for my brother in law.When I first finished the board I showed my wife but she thought it was just a little too small and needed a little more surface space. I ended up adding a border around it and that made it look much better. Congrats on the wedding guys.

Here you can see I used my milling machine at work to plane the faces flat. Sanding is not something that I enjoy doing so this makes quick work of flattening the cutting board. This is also something you can do with a router and a jig. I will go over this method at a different time.

Here you can see what it looks like after i added the border, great suggestion from my wife.

Ready to round over the edges I think it was a 1/4 round over bit. I do this to both side of the cutting board.

Ready for the finish !!!

I did not include any pictures of my sanding not very interesting anyway.

Now this is my favorite part of the whole process. Before i apply the finish I like to wipe my work down with mineral spirits. This just gives me some extra insurance that my finish will go on with out any problems.

Here she is all finished up. I used mineral oil to finish it off.

Labels:

projects

Wednesday, April 20, 2011

Ben & Kristen's cutting board PART 2

These are a couple of the tools that we use in the machine shop a dial indicator and the Mighty Mag. This set up will allow me to adjust the planer by one thousandth of an inch. One thousandth is not to realistic but ten thousandths sure is. This set up works really well when combined with calipers, since your tape measure can’t measure this fine.

Here is a zoomed out view of the set up. You can see how this works much better than the measuring tape on the actual machine. I also decided to cut a few new pieces of walnut after attempting to use epoxy to fix the cracks. I decided on this because the epoxy I used cured to fast and was to thick. I didn’t feel it was penetrating all the way into the crack. This would have left voids in the wood when cut and rotated to the end grain. I feel this was a much safer decision. The risk of gluing all the pieces up and finding out it didn’t turn out how I wanted was not worth it, plus I had the extra walnut.

Here are all the finished pieces. I ran all the pieces through the planer one last time. Doing this gave me a more uniformed finish and size compared to the planed full width boards.

Getting ready for a glue up.

I put a sheet of wax paper on my clamps before I actually applied the glue. I did this to help prevent the squeeze out from drying on my clamps.

Glue is on all I need to do is use a ink roller to spread it and we will be all glued up.

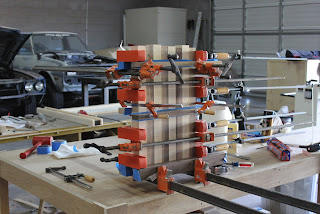

A few clamps anyone? Still need to get my glue ups down, glue seems to allways dry a little faster than you want. I was able to still get done before it was to dry but pre planning is the key to a good glue up.

Labels:

projects

Monday, April 11, 2011

Ben & Kristen's cutting board

I finally started working on my brother-in-laws wedding present today. He requested a custom made cutting board from my wife and she said, “where the heck am I going to get that.” To which he replied, “Anthony, duh.” It took Laura a couple of seconds to realize what he was talking about and said, “Oooooooh!”. This is funny because that’s one of the gifts she got for Christmas.

Laura's maple and padauk cutting board

I have made a rendering of what I want the cutting board to look like.

First I start by by modeling a single block on my cad system. I change the shading to the type of wood that I want it to resemble.

Then I save a new file as a new name and change the shading again to resemble the other wood that I will be using.

Now for the cool part, I start a new file as an assembly and insert both blocks, add a few mates and you start to have a cool looking strip of wood. Once this is done I save a new assembly, create a few more mates and do a liner pattern. The end result is what you see above.

This is the lumber that I started with. It is 8/4 hard maple and 8/4 walnut. This lumber is just under 6 inches wide. I forgot to take pictures before I cut the boards to 21 in long I believe the rough lumber was about 6 to 8 feet long.

This is a view from the end of the rough lumber. The one piece of walnut you can see a crack. I plan on using some epoxy to stabilize the wood.

I already trued up the lumber in the jointer and now I am running it through the planner. When I plane my lumber to thickness. I find using calipers much easier to make sure it is the correct thickness.

This is the planed walnut I really enjoy the color, smell and texture of this wood.

Lumber before I cut it into strips. I like to mark the side that I run against the fence and the side that runs down on the table.

Lumber after I have started cutting it into the strips 1.750 X 2.0 X 21.0.

All the pieces are cut. Before I do my glue up I have to address the crack in the walnut piece epoxy will work quiet well.

Labels:

projects

Subscribe to:

Posts (Atom)