These are a couple of the tools that we use in the machine shop a dial indicator and the Mighty Mag. This set up will allow me to adjust the planer by one thousandth of an inch. One thousandth is not to realistic but ten thousandths sure is. This set up works really well when combined with calipers, since your tape measure can’t measure this fine.

Here is a zoomed out view of the set up. You can see how this works much better than the measuring tape on the actual machine. I also decided to cut a few new pieces of walnut after attempting to use epoxy to fix the cracks. I decided on this because the epoxy I used cured to fast and was to thick. I didn’t feel it was penetrating all the way into the crack. This would have left voids in the wood when cut and rotated to the end grain. I feel this was a much safer decision. The risk of gluing all the pieces up and finding out it didn’t turn out how I wanted was not worth it, plus I had the extra walnut.

Here are all the finished pieces. I ran all the pieces through the planer one last time. Doing this gave me a more uniformed finish and size compared to the planed full width boards.

Getting ready for a glue up.

I put a sheet of wax paper on my clamps before I actually applied the glue. I did this to help prevent the squeeze out from drying on my clamps.

Glue is on all I need to do is use a ink roller to spread it and we will be all glued up.

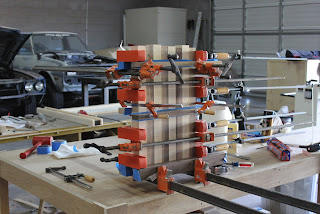

A few clamps anyone? Still need to get my glue ups down, glue seems to allways dry a little faster than you want. I was able to still get done before it was to dry but pre planning is the key to a good glue up.

No comments:

Post a Comment